Coping With Uncertain Times: Lean Processes Are Vital For Legal Ops

The impacts of the coronavirus have brought home the fact that companies need to make agility and responsiveness a tentpole of their business continuity planning. One way for Legal Operations groups to achieve that? By adopting lean business processes to improve collaboration and efficiency.

At various conferences and events over the past year, Brian McGovern, General Manager of Workflow Solutions (and Lean Six Sigma Master Black Belt), has guided attendees through a Lean Six Sigma journey. The purpose? To prove that Legal Operations can and should leverage Lean principles even when the company isn’t in a traditionally Lean-oriented industry, like manufacturing. The same holds true at many technology companies in product or software development.

So, to cover the basics of Lean and how they’ll benefit a legal department, we’re presenting this multi-part series about how it can be applied to Legal Ops processes.

A brief Lean history

First, remember the crux of Lean “is to maximize customer value while minimizing waste.” While this discipline was first employed within the manufacturing industry, with roots going back to the days of the Marshall Plan, W. Edwards Deming, and Kaizen, it’s grown in recent years to be relevant to other business sectors like healthcare, call centers, and software product development.

It started with Japanese loom production in the 19th century. Sakichi Toyoda obtained his first patent for the Toyoda wooden hand loom, leading to the Toyoda Automatic Loom with the built-in intelligence to stop if any threads were broken.

This was a case of building what became a pillar of today’s practice of Lean into the very technology of its time: a process, in this case the loom, stopping at a defect that would result in a product that’s unfit for use.

This was a case of building what became a pillar of today’s practice of Lean into the very technology of its time: a process, in this case the loom, stopping at a defect that would result in a product that’s unfit for use.

As technological advances around the loom kept coming, and other entrepreneurs started implementing similar processes to help their own production, Sakichi Toyoda’s son Kiirchiro came to the US and Europe to observe automobile production. These insights, along with the work of Taiichi Ohno and Shigeo Shingo and others, resulted in what we know as the Toyota Production System, designed around the Single Piece Flow and Just in Time methods of production refinement. And as we all know, American companies eventually began looking to Japan for more efficient business processes.

Six Sigma: The chocolate to Lean’s peanut butter

Six Sigma was introduced by Bill Smith while working as an engineer at Motorola in 1986. Its most impactful exponent, though, was undoubtedly Jack Welch, who built an entire massively successful business strategy upon Six Sigma while he led General Electric. Its name comes from a term used in statistical quality control and its objective is to improve the quality of the output of a process by identifying and removing causes of defects and “minimizing impact variability.”

Both Lean and Six Sigma had their origins in Japanese theories and practices around continuous improvement, so it’s no surprise they compliment each other:

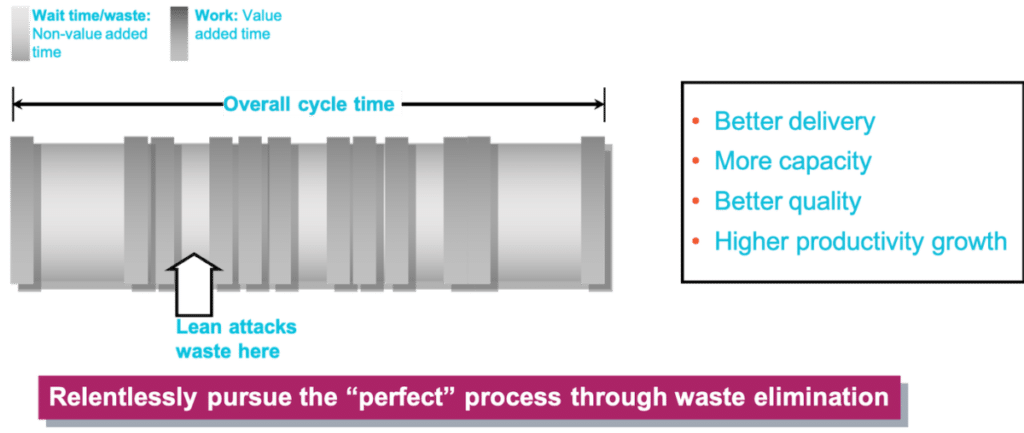

- Lean is a strategy for maximizing value to customers

- The relentless pursuit of the perfect process through waste elimination

- Focusing on the elimination of waste results in a competitive advantage in cycle time

- Six Sigma is a set of techniques and tools for process improvement

- This is accomplished via statistical analysis of the process to remove variation and defects

- Six Sigma refers to a statistical measurement of defects within a process; less than 3.4 defects per million process outputs

Maximizing value to the customer, wherever s/he is…

Together, Lean Six Sigma are about bringing maximum value to your clients (who are often internal stakeholders). Through a relentless pursuit of waste elimination, this results in competitive advantage for your team.

This pursuit of efficiency and error reduction is a big reason why manufacturing embraced automation, and why workflow automation is making inroads in corporate Legal Operations. Staffers can focus on doing truly productive work, becoming more responsive to client needs by not wrestling with repetitive, manual processes that are typically costly and prone to mistakes.

Why it matters to Legal Ops

Faster (when done right) is better. To get there isn’t always easy, and it most likely means you have to review current processes and how to make these more efficient. You’re not alone, as companies and departments across the globe are all fighting what seems like an endlessly uphill battle.

Everyday Legal Ops activities like NDA and contract lifecycles, ticket resolution, development, or managing requests should all commonly become Lean processes. Lean is comprised of 5 main principles: value, value streams, flow, pull, and continuous improvement.

After your team evaluates existing processes based on these steps, not only will you have a clearer picture of your processes, but you’ll possess a vision of what it’ll take to adapt these processes or adopt news ones to reach a new value plateau.

- Define Value based on the customer’s expectations

- Understand the Value Stream and identify waste

- Work to establish Flow wherever possible

- Focus on Pull from the customer where flow is not possible

- Continuously improve the process towards Perfection

Quick and useful definitions

- Value: Relative worth, utility, or importance – Always defined by the customer

- Value Stream: Series of actions (value-add and non-value-add) required to deliver a product/service to your customer

- Cycle Time: actual duration of a task from start to finish (calendar time)

- Work Time: shortest time currently possible to complete a task

- Value-Added Time (VAT): amount of work time that is spent adding value to the final product or service

- Non-Value-Added Time (NVAT): amount work time consumed by activities that do not add value to the final product or service, such as waste

With that groundwork out of the way…exactly what’s involved in the five steps?

Identify Value

Identify Value

You’re focused on your clients; these can be internal colleagues in different departments or external clients you serve. Everything you do is for their betterment and to help them meet the challenges they face. In Lean, the client/customer defines value. If they wouldn’t pay for the “products” provided by you, then those aren’t considered valuable. Mapping the Value Stream and Identifying wastes to control is key to iterating on more valuable “products” for your Legal Ops organization.

Map the Value Stream

Map the Value Stream

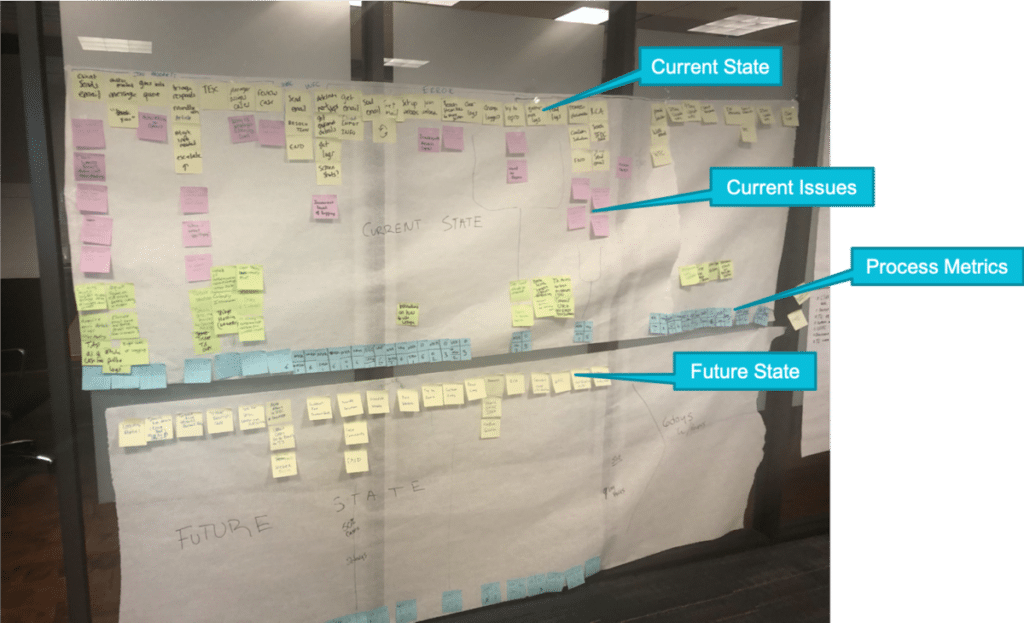

In order to streamline any process, it’s important to understand what that process actually looks like at its current state – right or wrong. This is done visually, and it’s an exercise that involved someone from all teams involved, including the end user / client, if possible. This elicits collective knowledge and subject matter experts who will help refine the process to maximize its value.

Once mapped step-by-step, the team goes through each step to identify the work time, cycle time, and value-add within that step. After this comes the process of eliminating the 7 main types of waste Lean Six Sigma identifies. The goal of this step? To map the best possible future state of the process. Here’s what you might end up with:

Assess Opportunities of Current State

Assess Opportunities of Current State

In order to allow the best assessment of your current state and what it means to your business right now, it’s vital to question everything by calling upon a diverse set of users and stakeholders; this means that you’ll head into your conversations about that optimal “future state” with more concrete ideas. Often this is the time to employ the “5 Whys” technique, a Six Sigma root cause analysis technique to identifying the source of problems or the real value (or lack of value) of an existing process.

Once you understand each step of a process, and the value it is or isn’t adding, you can make improvements since you now know where you can control or eliminate waste.

Map the Future State of the Process

Map the Future State of the Process

What would a perfect process look like? Don’t worry about the dependencies you may have on another team or what steps seem necessary based on your current process. Begin with an Ideal Result that is purely a value-add for your service. Apply knowledge gained from the Current State exercise, while keeping in mind the critical components of customer, supplier, material flow, and information flow.

Implement Future State

Implement Future State

Once you know what the future state looks like, use it as your guide to making changes to your Legal Ops processes in order to optimize your legal department’s services. Develop actionable plans to help this transition between current and future processes, then implement your improved process. And, just as importantly, measure, monitor, and manage these changes to see what impact they’re having, and adjust if necessary.

That’s it! It takes some time and dedication to put it all into practice, but in times like these? Many corporate legal departments are being forced to change simply to keep up with the changes in the world outside, changes that are profoundly affecting the enterprises they serve.